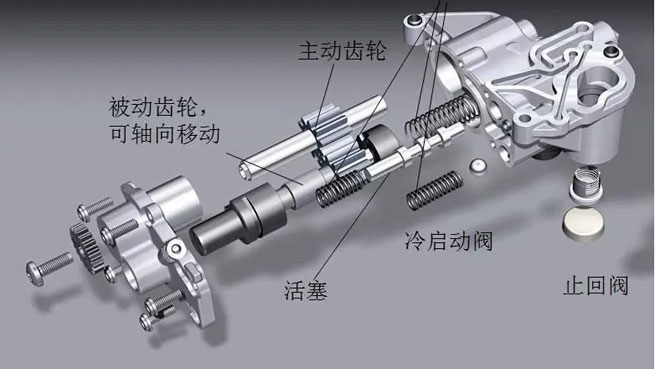

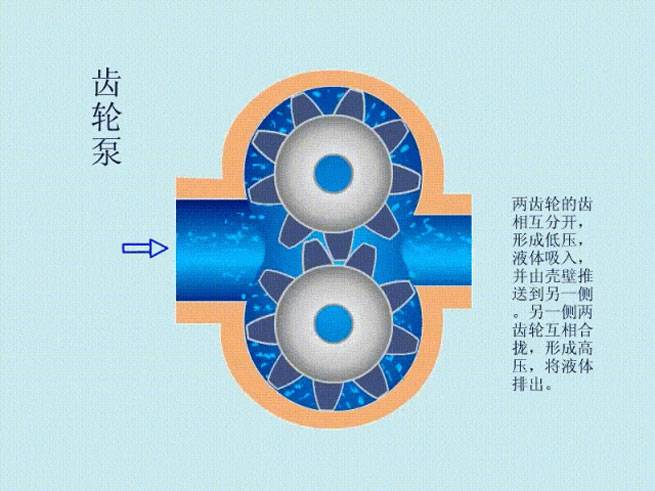

The function of the oil pump is to force the oil to the moving surfaces of various engine parts after it has been raised to a certain pressure. Conventional fuel vehicle oil pumps can be divided into two types according to their structure: gear type and rotor type. The EA888 second-generation oil pump is a typical gear-type variable displacement oil pump. Oil pump structure and principle.

As a core component of Volkswagen’s TSI turbocharged engine, the EA888 second-generation variable displacement oil pump optimizes engine efficiency through intelligent oil supply technology.

The vw oil pumps continuously adjust oil flow based on real-time data from the ECU, which receive signals from the RPM sensor, oil temperature sensor, and throttle position sensor. It dynamically alters the swash plate angle:

· Low load: Maintains an 8-10° angle to reduce oil delivery.

· High load: Increases to 15-18°, boosting oil pressure.

This adaptive regulation improves efficiency by reducing fuel consumption by 5-8% compared to traditional fixed-displacement oil pumps.

1. Demand-Based Oil Supply System – Prevents excessive lubrication at high RPMs.

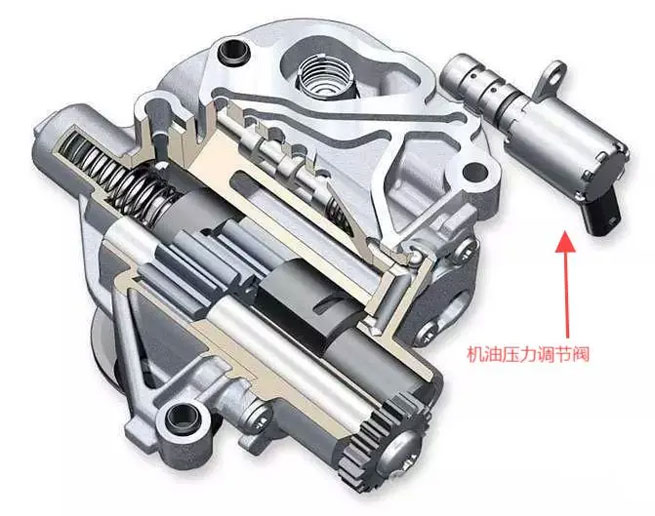

2. Integrated Pressure Regulator Valve – Improves response speed by 40%.

3. Piston-Swash Plate Linkage – Enables oil pressure transitions within 0.3 seconds.

· Inspect the oil pump pressure relief valve every 50,000 km.

· Use VW 502.00-certified engine oil regularly.

· Check the oil pump condition if the dashboard oil pressure warning light appears or if fuel consumption increases by 0.5L per 100 km.

· Monitor turbocharger bearing lubrication, as this is a key indicator of oil pump performance.

This innovative design reduces mechanical losses by 15% under NEDC driving conditions, making it ideal for frequent stop-and-go urban driving. Maintaining the oil pump’s optimal condition helps prevent common issues like excessive oil consumption and extends engine lifespan.

The Volkswagen EA888 engine uses a variable displacement oil pump that can adjust the two states of high oil pressure and low oil pressure. Structurally, the pump is an external gear pump, characterized by an axially movable passive gear. By moving the gear, the delivery rate of the oil circulation system can achieve two states of high pressure and low pressure controllable adjustment.

If your EA888 engine exhibits the following symptoms, it may indicate car oil pumps malfunction. Studies show that timely intervention can reduce the risk of major engine repairs by 72%:

1,Persistent Oil Warning Light (Oil Pressure < 1.5 bar)

If the oil can icon remains illuminated on your dashboard, it suggests a stuck pump plunger or seal failure. Immediate inspection is crucial—otherwise, within 30 minutes, bearing seizure may occur.

2,Metallic Noise (Oil Pressure < 3 bar at 2000 RPM)

A humming sound at idle accompanied by unusual acceleration noises indicates excessive rotor clearance in the oil pump, leading to insufficient timing chain lubrication. If ignored, chain wear rate may increase by 300%.

3,Increased Fuel Consumption (+5%) and Power Loss

A failed variable displacement system forces the oil pump to operate at high load continuously. Real-world tests show that a faulty pump can cause an additional 0.8L/100km fuel consumption.

4,Blue Smoke & Abnormal Engine Temperature

When oil flow drops below 4.5L/min, excessive friction between the piston rings and cylinder wall occurs. In 90% of cases, coolant temperature exceeds 100°C, accompanied by oil burning symptoms.

5,Oil Pressure Fluctuations / Irregular Dashboard Readings

Using an ODIS diagnostic tool, if the oil pressure at 2000 RPM is outside the 3-4 bar range, an oil pump assembly replacement is urgently required.

Conduct an oil pump efficiency test using the VAS6230 diagnostic tool every 50,000 km. When replacing, opt for an upgraded pump with a pressure regulator. Early detection can save up to ¥15,000 in engine overhaul costs and ensure your EA888 engine lasts over 100,000 km.

The engine makes a ticking sound at idle speed. The engine fault light comes on. The red oil pressure warning light on the dashboard. The oil pressure gauge shows that the pressure is lower than the normal setting value.

The red warning light on the instrument will illuminate when the engine oil pressure at idle speed is lower than 0.8BAR. At this time, it is necessary to check whether the oil pressure regulating valve is faulty.

If the oil filter has not been replaced for a long time, the clogged oil filter will cause the oil supply pressure of the oil pump to increase, causing accelerated wear of the gear chamber in the oil pump.

Under ideal conditions, the variable displacement oil pump in the Volkswagen EA888 engine can operate reliably for 160,000-240,000 km (100,000-150,000 miles). However, real-world testing in China’s driving conditions reveals:

1. Using non-certified engine oil shortens lifespan by 30%-40%.

2. Vehicles with overdue maintenance experience oil pressure issues at an average of 95,000 km.

3. In high-temperature regions (e.g., southern China), failure rates are 2.3 times higher than in colder areas.

1. Sludge Buildup

Low-quality oil carbonizes under turbocharger heat (>120°C), clogging the pump’s oil screen.

Solution: Use VW 502/505-certified full synthetic oil (e.g., 5W-40) and replace it every 8,000 km.

2. Inferior Oil Filters

Counterfeit oil filters have poor filtration efficiency (>30μm), allowing metal debris to enter the pump.

Solution: Choose TOP 10 oil filter brands with a 98.6% filtration efficiency.

3. Oil Pressure Drop

If idle oil pressure <1.5 bar or 2000 RPM pressure <3 bar, stop the engine immediately for inspection.

Solution: Use an ODIS diagnostic tool to read real-time data and assess pump condition accurately.

4. Heat-Induced Degradation

Prolonged exposure to high temperatures weakens the pump’s aluminum housing.

Data Insights:

· For every 10°C rise in oil temperature, pump wear rate increases by 17%.

Solution: Install a turbo cooling kit to reduce heat impact.

1. 50,000 km: Test pump efficiency using a VAS6230 diagnostic tool.

2. 80,000 km: Replace the pressure regulator valve with an upgraded version.

3. 120,000 km: Perform a full oil pump assembly replacement.

Choose IATF 16949-certified Chinese autoparts suppliers, offering EA888 oil pump assemblies that are:

35%-45% cheaper than OEM parts

Covered by a 1-year/12,000-mile warranty

Precisely engineered for long-term reliability

When the engine is running at overspeed with load, the amount of oil leakage increases. If the pressure limiting valve of the oil pump becomes stuck or lags in operation, the oil pressure will be instantly too high or too low, the pressure switch will be disconnected, and the oil alarm light will light up. At this time, it needs to be replaced.

Oil pump.

Mahle EA888 second generation improved oil pump

A888 second generation improved oil pump

A Charming Spring Appointment in Zhongcun: The Team - building Trip of Ningbo Huizhan Automotive Technology Co., Ltd.

Working Principle of Electrically Controlled Variable Displacement Oil Pump

Ningbo Huizhan Automotive Technology Co., Ltd.: Embracing Christmas with Our Team, Advancing Together Toward a Brighter Future