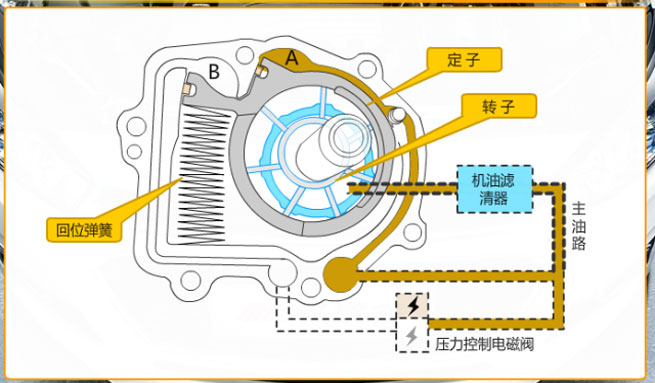

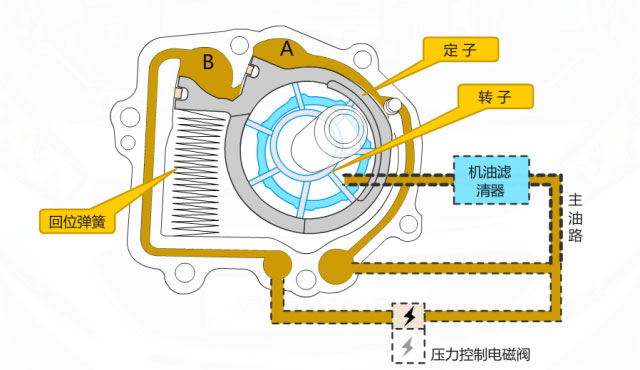

Figure 2 Electronically controlled variable displacement oil pump

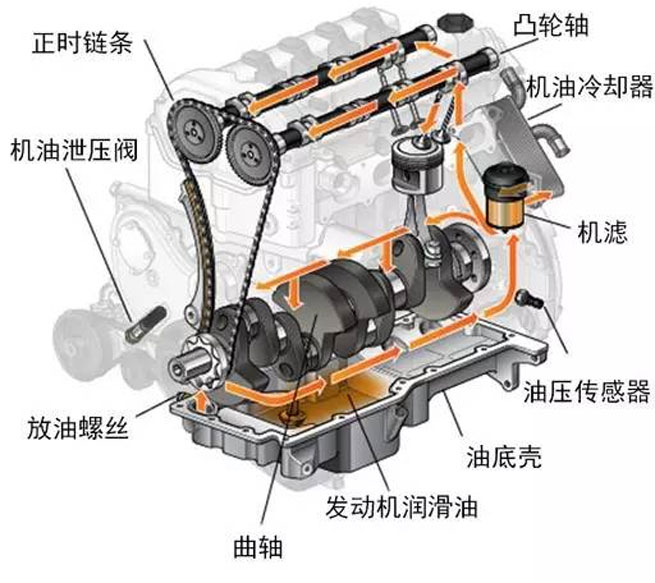

As we all know, the oil pump is the heart of the engine lubrication system. As shown in Figure 3, the oil pump draws oil from the oil pan and continuously provides pressure lubricating oil to all friction parts of the entire engine. If the oil supply of the oil pump is insufficient, the engine will lack sufficient lubrication pressure, causing severe engine wear. But if the fuel supply is always maintained at a very high level, it will inevitably increase the internal loss of the engine and cause unnecessary waste. Therefore, we need the oil pump to be able to provide the best amount of oil according to the needs of the engine. This requires the variable displacement oil pump to show its talents!

Figure 3 Principle diagram of engine lubrication system

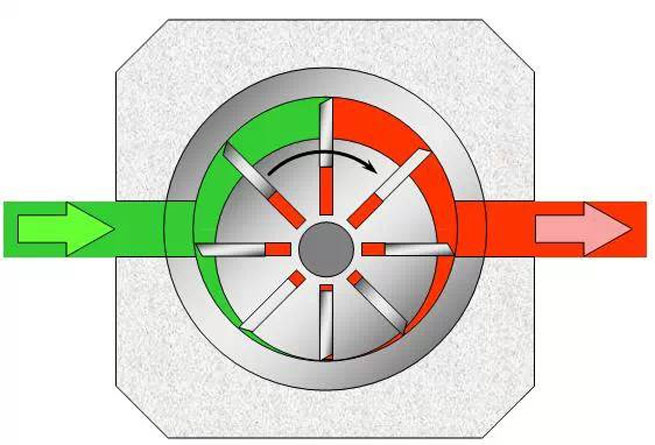

First, we need to understand the working principle of the new generation of small displacement engine oil pump. The core part of this oil pump is a vane structure.

Figure 4 Basic working principle of vane oil pump

As shown in Figure 4, due to the eccentric arrangement of the stator and rotor, as the rotor rotates clockwise, the space between the two blades of the left chamber gradually increases, forming a vacuum and absorbing oil; the space between the two blades of the right chamber gradually increases. The space gradually decreases, pressure is formed, and oil is released. In this way, the rotor continues to rotate under the drive of the crankshaft, and the engine oil is continuously pumped out.

Of course, this is just a simple fixed displacement pump. How can the displacement be adjusted? Because this kind of oil pump relies on the eccentric setting of the rotor and stator to achieve the oil pumping effect. If the eccentricity between the rotor and the stator is reduced, the spatial change between the blades will become smaller when the rotor rotates, and the amount of oil pumped per revolution will also become smaller.

GM's new generation of small-displacement engines use this principle to adjust the oil pump displacement.

When not working, the stator of the oil pump maintains the maximum eccentricity with the rotor under the action of the return spring. As shown in Figure 5. The displacement is also the largest at this time. There are two oil chambers A and B between the stator and the outer wall of the oil pump. These two oil chambers are the most critical factors in adjusting the displacement of the oil pump. Chamber A introduces the main oil pressure through the filter, while the oil pressure in chamber B is controlled by a solenoid valve. When the engine computer energizes the solenoid valve and opens it, the oil pressure in the main oil circuit will act on chamber B, and together with the pressure in chamber A, push the stator counterclockwise. In this way, the eccentricity between the stator and the rotor is reduced, and the displacement is also reduced. As shown in Figure 6.

Figure 5 Large displacement state

Figure 6 Small displacement state

As we all know, at idle speed, the engine speed and load are minimum, and the engine oil supply required by the engine is relatively small. At this time, the engine computer energizes the solenoid valve to reduce the displacement of the oil pump, reducing engine running resistance and saving fuel. As the speed and load increase, when the engine computer determines that a large displacement is needed, it cuts off power to the solenoid valve, and the oil pump returns to a large displacement.

It can be seen from the control principle that once the solenoid valve fails, it is equivalent to a power outage of the solenoid valve, and the oil pump will maintain a large displacement state. At this time, sufficient engine lubrication needs can be ensured. However, since small displacement control cannot be achieved, its fuel economy will be sacrificed.

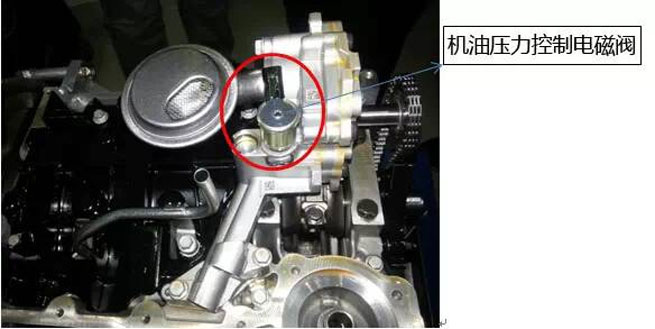

This oil pump is not allowed to be disassembled for maintenance. If there is a malfunction, the assembly needs to be replaced. There is a pressure sensor installed on the main oil circuit of the engine, which can read oil pressure data and oil pressure control solenoid valve commands through GDS to help us judge the performance of the oil pump. An oil pressure gauge can also be installed, and the oil pressure should not be lower than 180 kPa when idling and the engine oil temperature is greater than 85 degrees Celsius. (Note: If the oil pressure is low, it may not necessarily be a problem with the oil pump. It could also be caused by low oil viscosity, engine oil circuit blockage, or wear of the engine crankshaft main journal.)

The control principle of the variable displacement oil pump of the engine can be summarized as follows: it has the function of actively controlling the displacement of the engine oil pump by the computer. When powered on, the displacement is small; When there is a power outage, the displacement is large. When the solenoid valve fails, it can still ensure sufficient supply of engine lubricating oil.